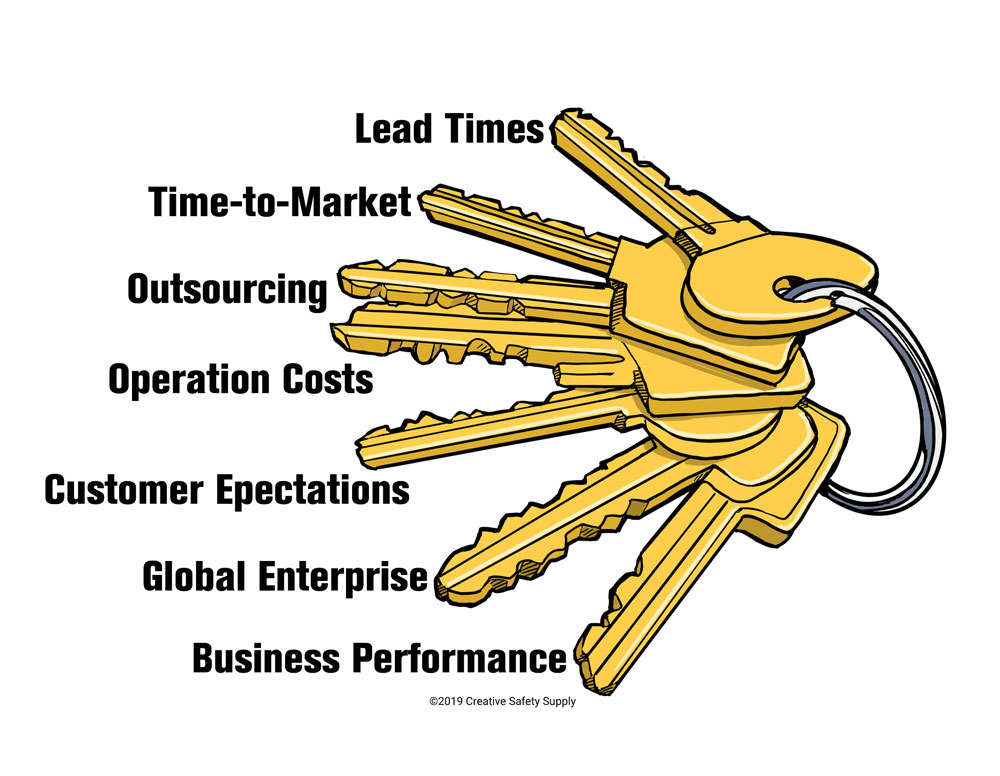

Now, in World Class Manufacturing, Schonberger returns to tell the success stories of nearly 100 American corporations including HewlettPackard, HarleyDavidson, General Motors, Honeywell, and Uniroyal that have adopted the famed justintime production and "total quality control" strategies Based on his firsthand experience as a major consultant to American industry, he examines how they did it and illustrates how the same concrete, specific steps used by these top companies canThe World Class Manufacturing (WCM) is an integrated system that brings the excellence of the entire logistics cycle and production of an undertaking by Continuous improvement of all services;Another vital component of worldclass manufacturing is adaptability "I see flexibility for change and the ability to meet customer requirements as far as delivery times and quality of products to be parts of worldclass manufacturing," says Scott Huber, polymer production manager with Adhesives Research Inc, Glen Rock, Pa

Management Systems Yaris Kabin

World class manufacturing wiki

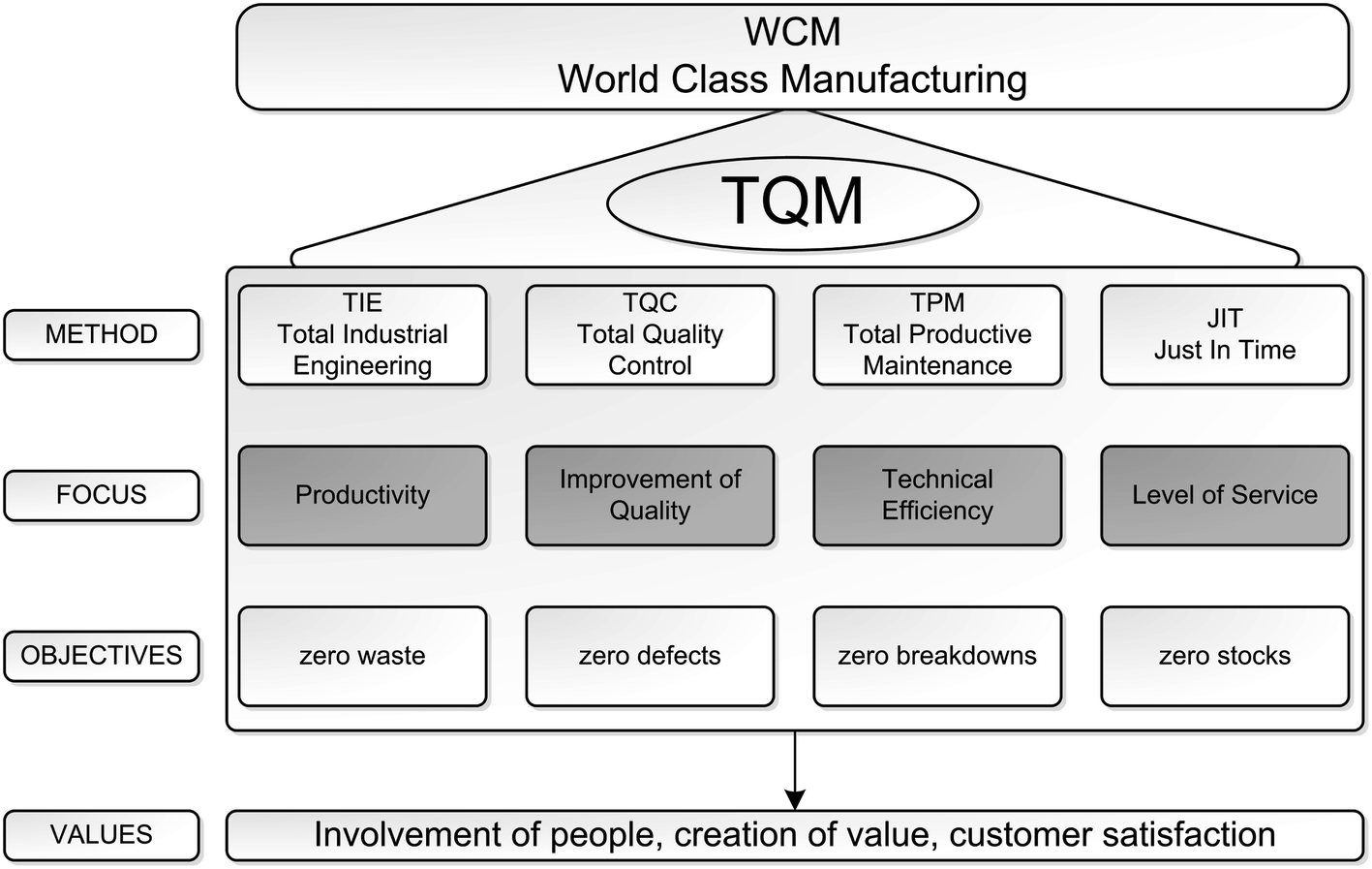

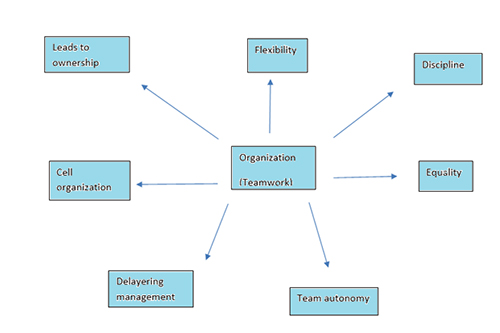

World class manufacturing wiki-Involvement of all levels and functions;World Class Manufacturing is a management concept, which can be translated as production on a global level philosophy of WCM in the manufacturing plant has decreased misfortunes and improved the quality of the items World Class Manufacturing is an administration idea, which can be interpreted as a creation on a worldwide level

World Class Manufacturing Fca Group

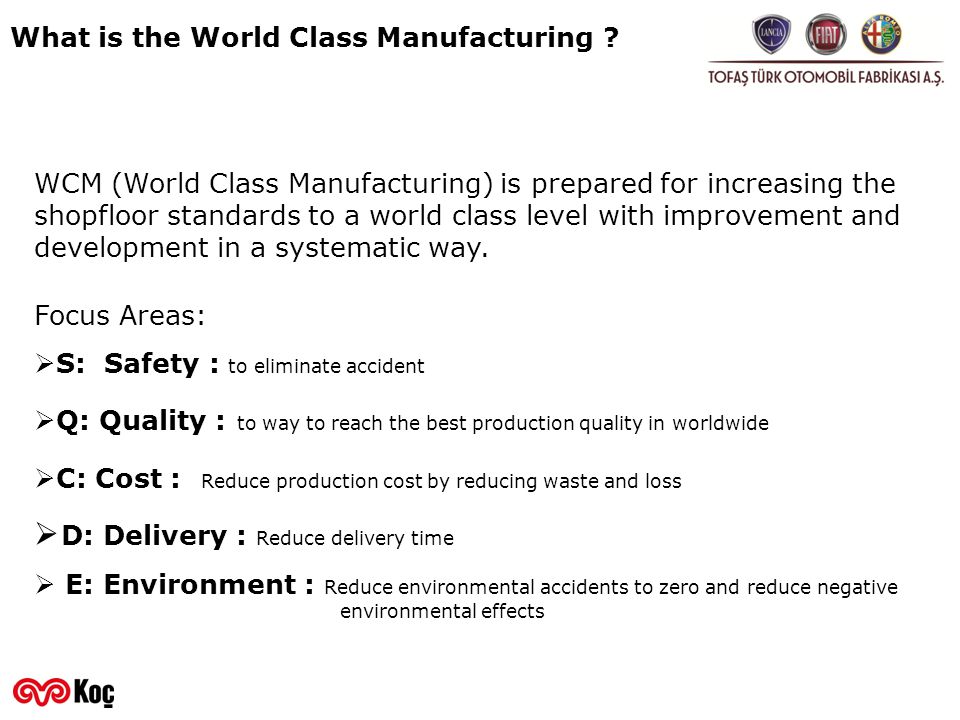

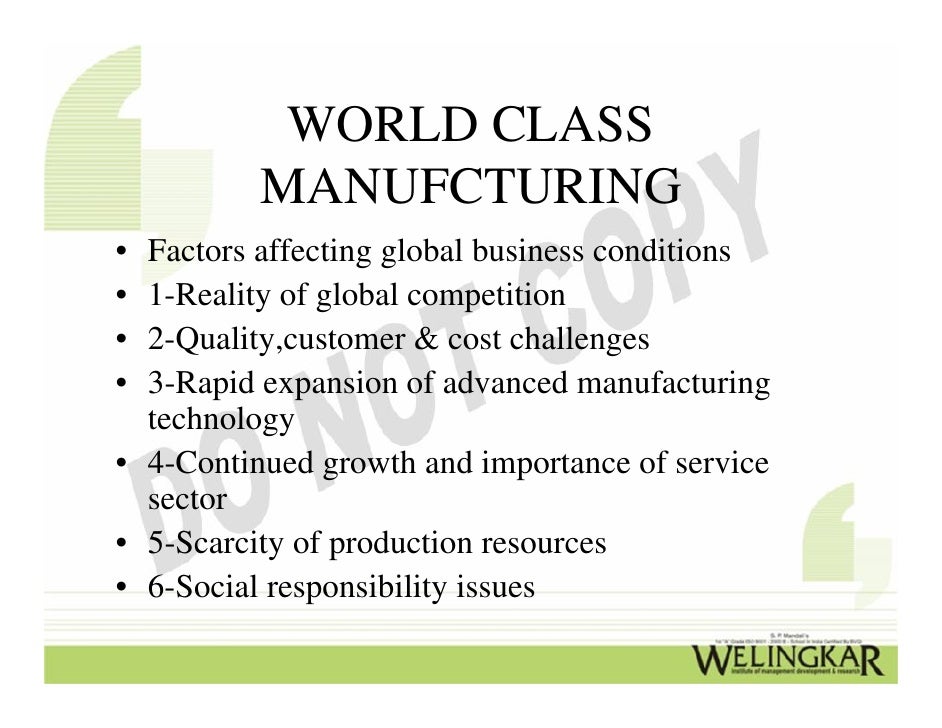

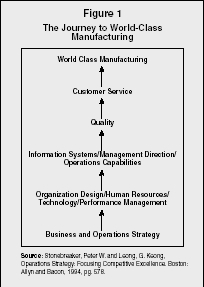

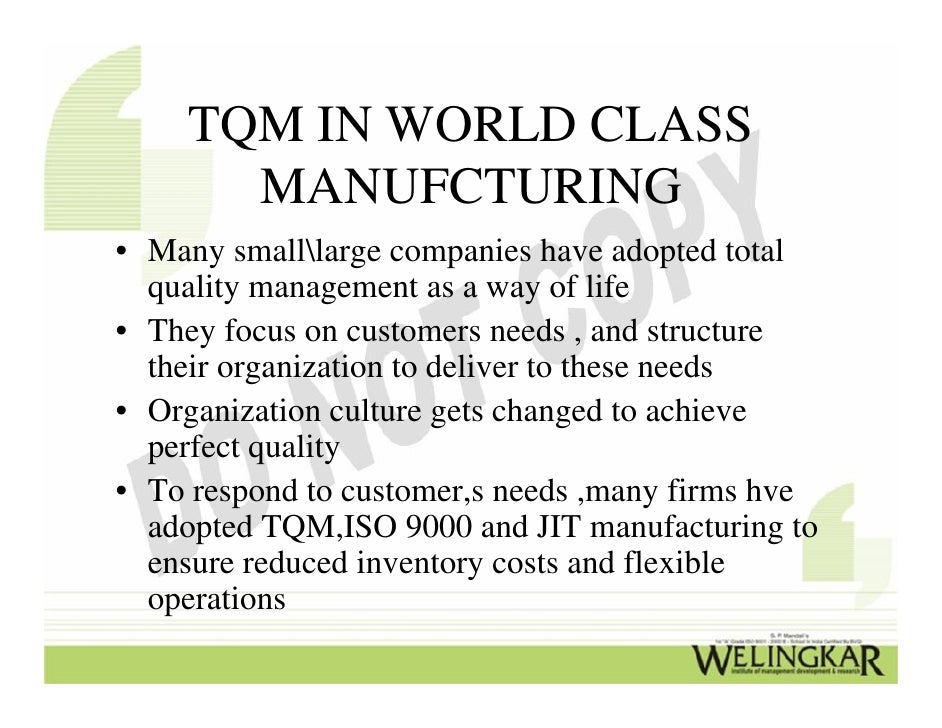

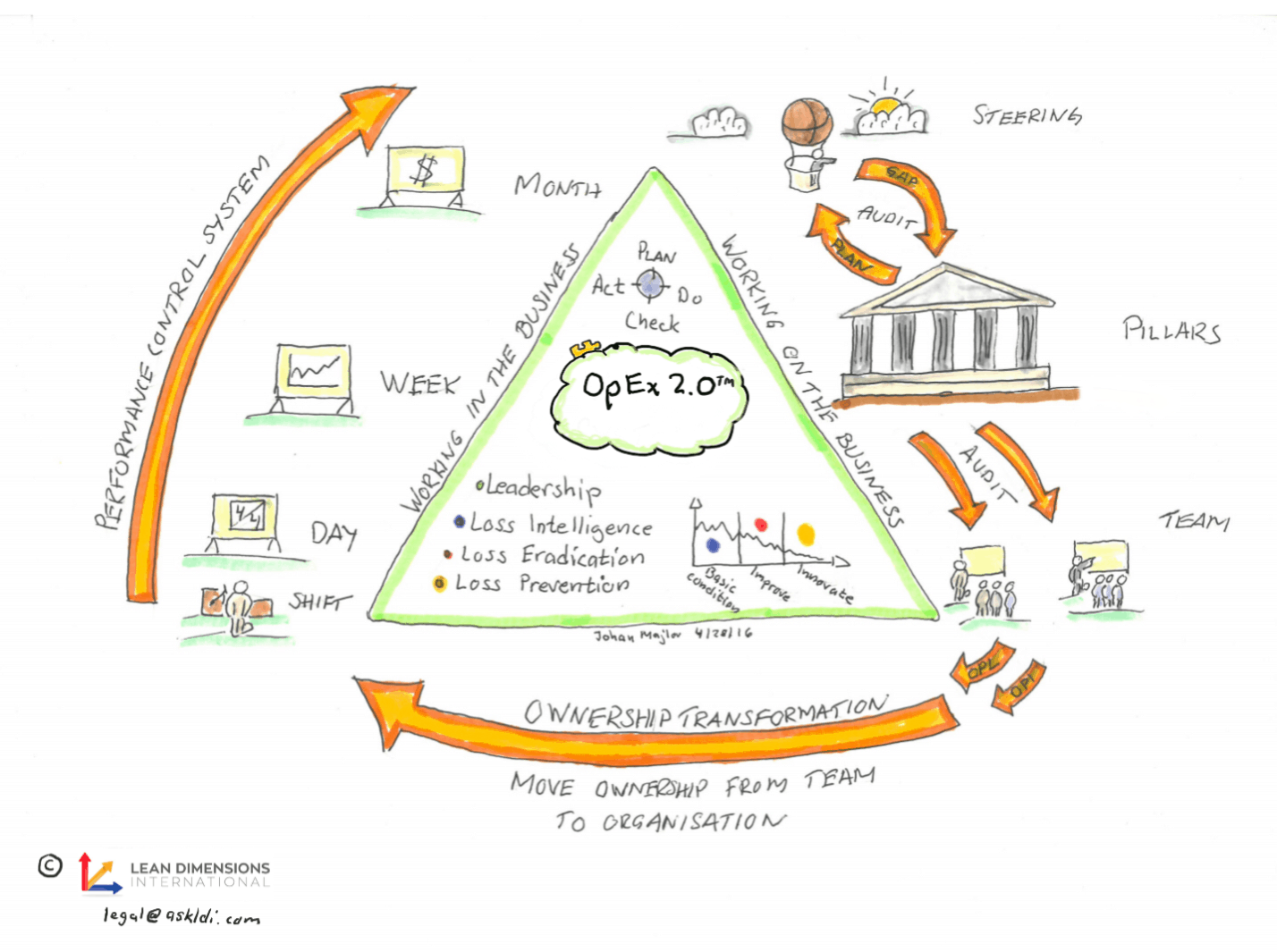

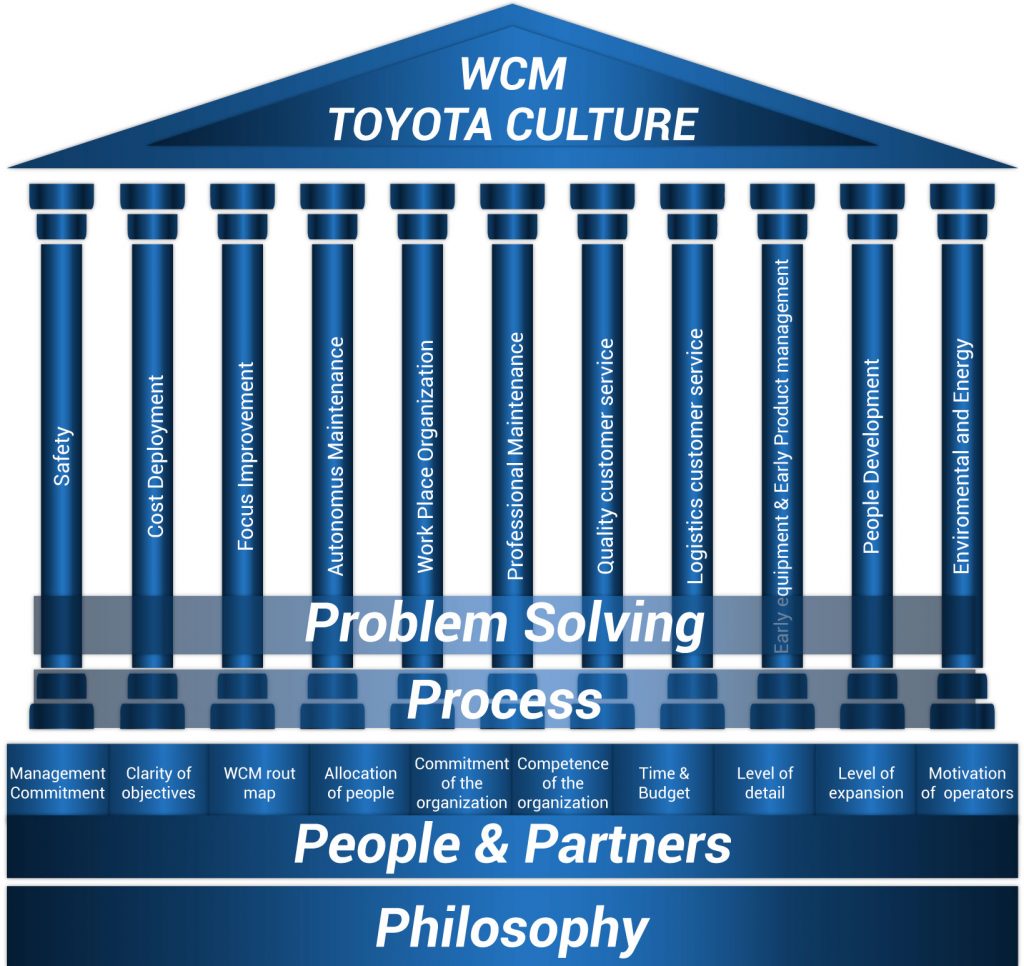

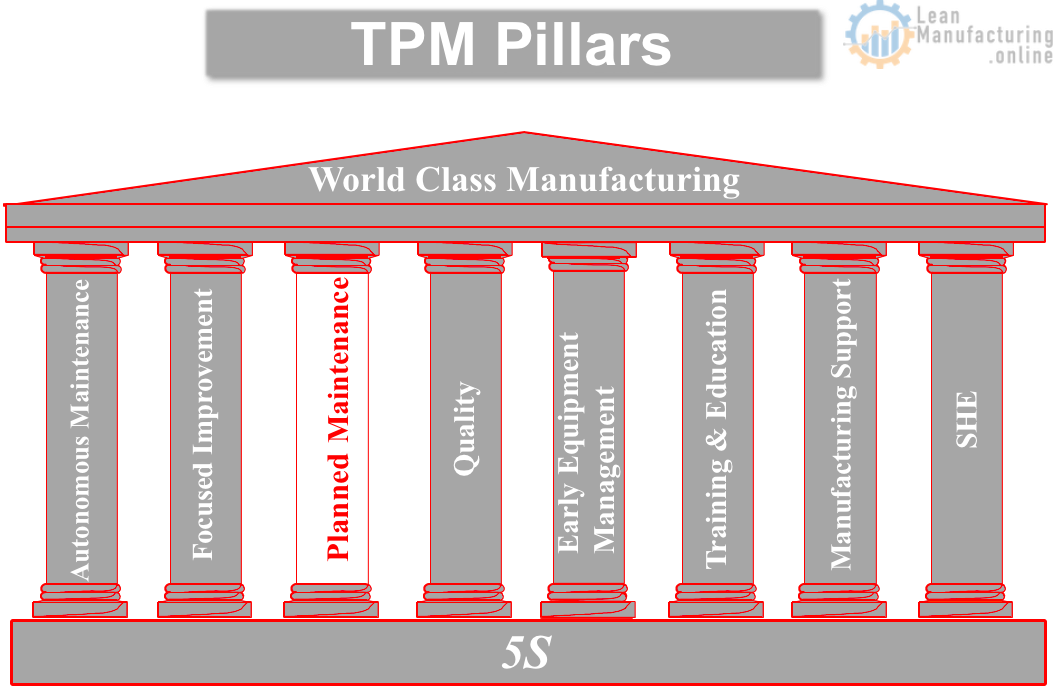

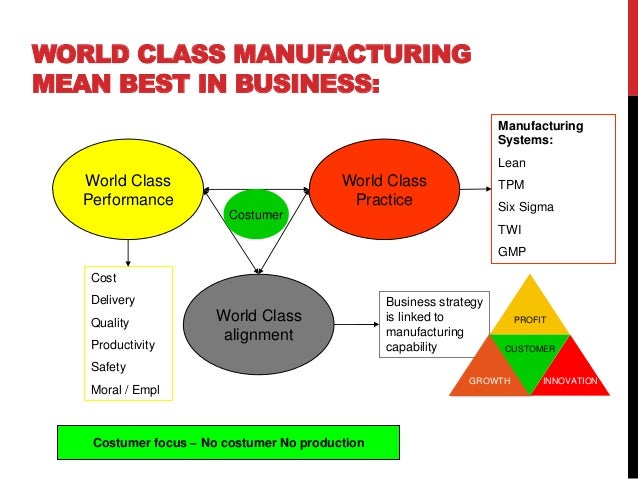

Now, in World Class Manufacturing, Schonberger returns to tell the success stories of nearly 100 American corporations including HewlettPackard, HarleyDavidson, General Motors, Honeywell, and Uniroyal that have adopted the famed justintime production and "total quality control" strategies Based on his firsthand experience as a major consultant to American industry, he examines how they did it and illustrates how the same concrete, specific steps used by these top companies canAccording to Gunn (1987), WorldClass manufacturing rests on three pillars namely Computer integrated manufacturing (CIM), total quality control (TQC) and justintime (JIT) production methodsThe main objective of this paper is to enumerate the basic concepts, principles, benefits and barriers of world class manufacturing practices WORLD CLASS MANUFACTURING PRACTICESThere are many world class manufacturing practices that help the organizations to achieve their goals more effectivelyWorld Class Manufacturing (WCM) is a structured, rigorous and integrated production methodology adopted at FCA plants worldwide, which involves the entire organization, from safety to environment, maintenance, logistics and quality The primary objective of WCM is continuous improvement in all areas of production in order to guarantee the quality of the final product and meet customer expectations

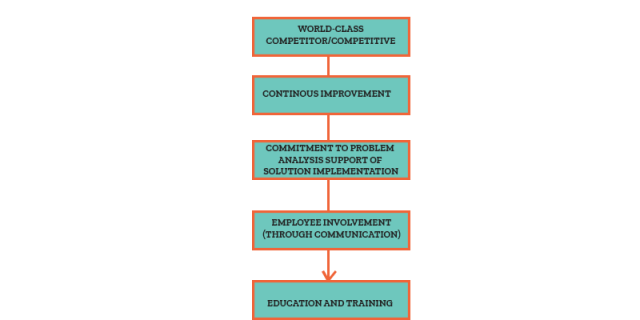

Definition• Aiming to compete for quality on a world wide market and becoming competitive in global market• A position of international manufacturing excellence, achieved by developing a culture based on factors such as continuous improvement, problem prevention, zero defect tolerance, customerdriven justin time production, and total quality management 24 July 12 2Here are our "top six" essential manufacturing KPIs to get you started 1 Overall equipment effectiveness (OEE) OEE is a much talked about KPI and shows how manufacturing assets perform relative to their theoretical maximum potential Businesses that invest heavily in plant will find that OEE measurement is an essential metric to trackWorld Class Manufacturing also includes Schonberger's 17point action agenda to guide innovators toward manufacturing excellence, from getting to know the customer to cutting the number of suppliers, reducing error in production, and deciding when and how to automate

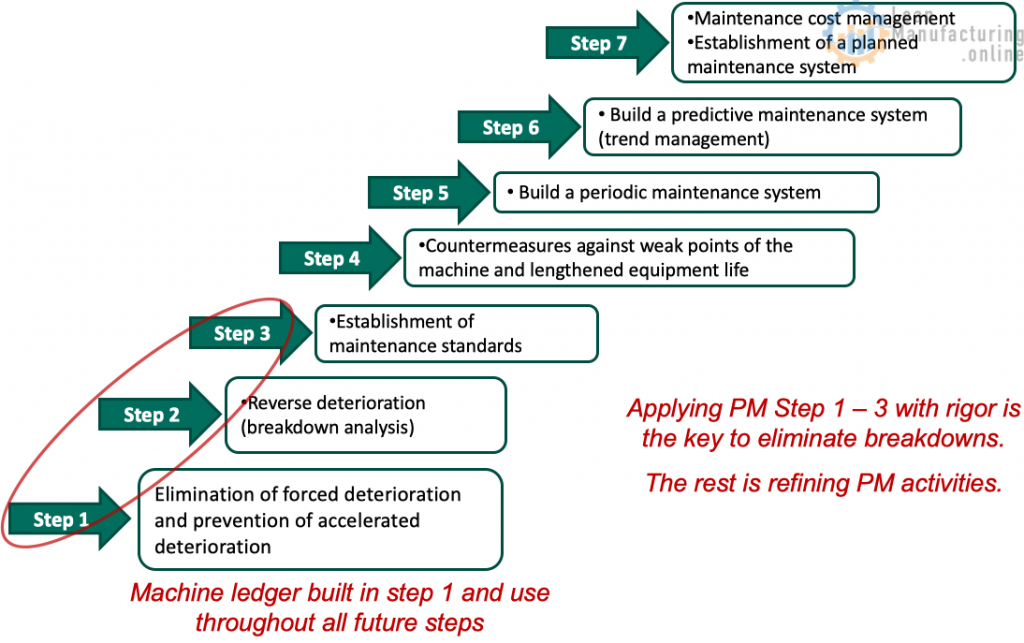

It is part of the "Overall Equipment Effectiveness" (OEE) metric A production schedule that includes down time for preventative maintenance can accurately predict total productionWorld class manufacturing (wcm) 1 World Class ManufacturingByDeepti Anand (066)Rahul Hedau (073)Amit Sharma (080)Shilpa Sharma (087)Komal Sachan (094)Kanad Kale (101)Manisha Mishra (108)Ritika Mittal (115)Tushar Mehta (122) 2 Definition• Aiming to compete for quality on a world wide market and becoming competitive in global market• A position of international manufacturing excellence, achieved by developing a culture based on factors such as continuous improvement, problem preventionNow, in World Class Manufacturing, Schonberger returns to tell the success stories of nearly 100 American corporations including HewlettPackard, HarleyDavidson, General Motors, Honeywell, and

World Class Manufacturing 4 0

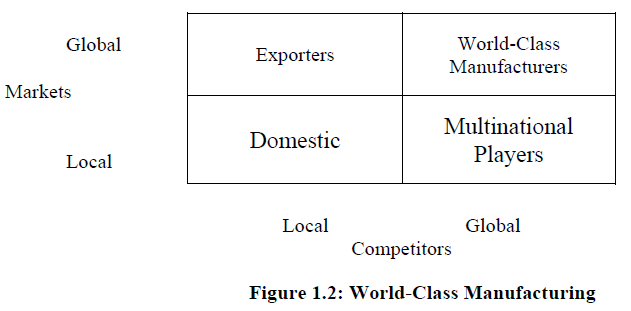

Wcm U2 Topic 3 Schonberger S Framework Of Wcm Gunn S Model

World Class Manufacturing PM – Machine Ledger and PM Calendar Planned Maintenance TPM World Class Manufacturing February 27, 0 1,294 Prioritizing the Equipment and Selecting the Maintenance System Blog December 23, 18 0 9 Breakdown Recurrence Matrix Blog Quality Training June 3, 18Becoming a World Class Manufacturing (WCM) company is a common industrial goal Muda and Hendry (02) which compels organisations to be among the best in the world in their type of business Todd (1995) They become competitive on a global basis, Kanter (1995) cited in Muda and Hendry (02) The termDefinition• Aiming to compete for quality on a world wide market and becoming competitive in global market• A position of international manufacturing excellence, achieved by developing a culture based on factors such as continuous improvement, problem prevention, zero defect tolerance, customerdriven justin time production, and total quality management 24 July 12 2

World Class Manufacturing Schonberger Richard J Amazon Com Books

Gkn To Build New World Class Manufacturing Facility In Japan E Hike

What is World Class Manufacturing?WORLD CLASS MANUFACTURING Element Food Solutions is sharp Element Food Solutions breaks through Element Food Solutions is ontarget Whatever your food manufacturing challenge, that's our challenge too Consider us a true extension of your operation We expand the boundaries of what's possible in manufacturing with unmatched expertise and unrivaled resources to innovate with youAccording to Gunn (1987), WorldClass manufacturing rests on three pillars namely Computer integrated manufacturing (CIM), total quality control (TQC) and justintime (JIT) production methodsThe main objective of this paper is to enumerate the basic concepts, principles, benefits and barriers of world class manufacturing practices WORLD CLASS MANUFACTURING PRACTICESThere are many world class manufacturing practices that help the organizations to achieve their goals more effectively

How Augmented Reality Can Support World Class Manufacturing Inglobe Technologies

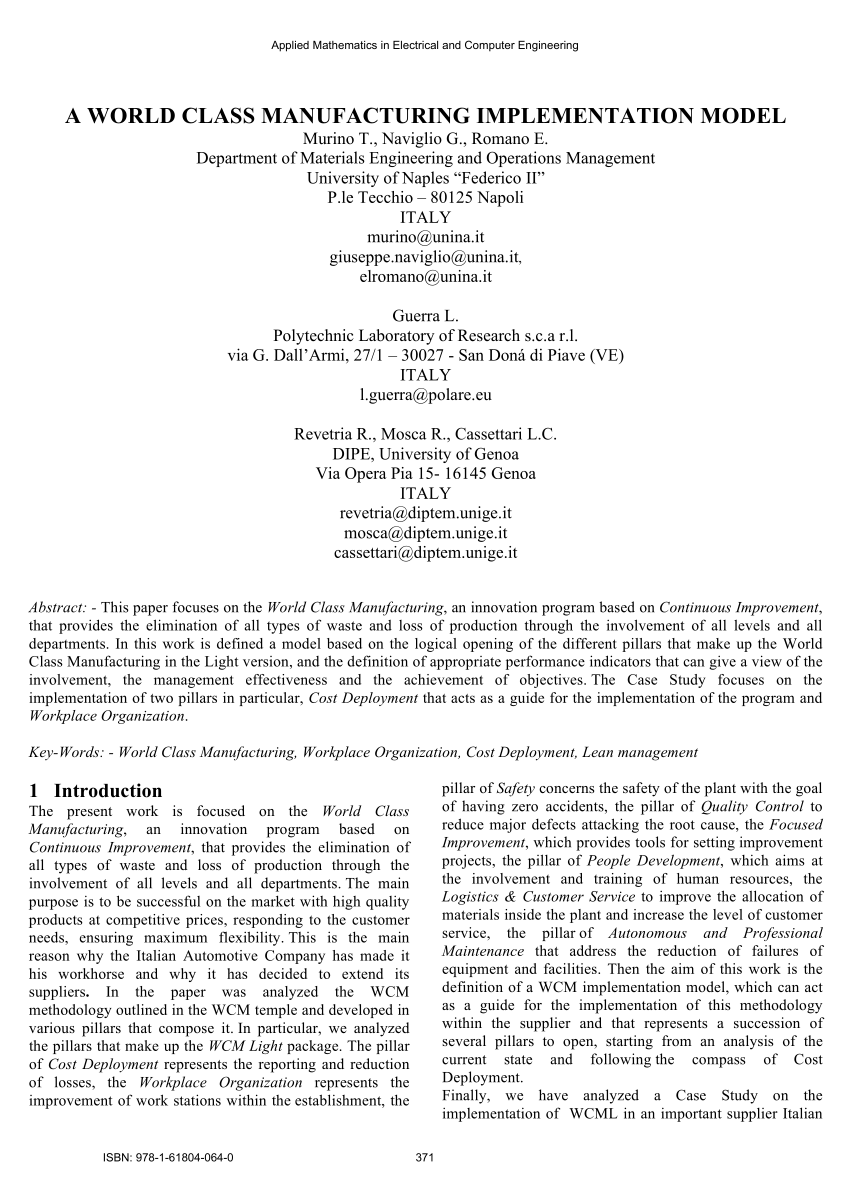

Pdf A World Class Manufacturing Implementation Model Semantic Scholar

World class manufacturing is a group of concepts, which develops standards for production and manufacturing for another organization to follow Japanese manufacturing is attributed for revolving the notion of worldclass manufacturing World class manufacturing was introduced in many sectors like automobile, electronic and steel industryWorld Class Manufacturing In his bestselling book Japanese Manufacturing Techniques, Richard J Schonberger revolutionized American manufacturing theory and, more important, practice In thatWorld Class Manufacturing ("WCM") is a set of concepts, set out as policies and principles developed for the operation and management of a manufacturing organization Their focus on driving the organization towards becoming a lean mean machine with costeffective and flexible operating processes

Organizational Culture Requirements For The Achievement Of World Class Manufacturing Springerlink

Fos Part I A Roadmap To World Class Manufacturing Execution Manuficient Consulting

Our mission is to help WorldClass Manufacturers become even more profitable Feel free to explore our website You will find several articles, videos, and other tools that will help you create an efficient and reliable production Click here Oskar Olofsson founded the company From our office in Stockholm, Sweden, we offer global consulting servicesNow, in World Class Manufacturing, Schonberger returns to tell the success stories of nearly 100 American corporations including HewlettPackard, HarleyDavidson, General Motors, Honeywell, and Uniroyal that have adopted the famed justintime production and "total quality control" strategies Based on his firsthand experience as a major consultant to American industry, he examines how they did it and illustrates how the same concrete, specific steps used by these top companies canNow, in World Class Manufacturing, Schonberger returns to tell the success stories of nearly 100 American corporations including HewlettPackard, HarleyDavidson, General Motors, Honeywell, and Uniroyal that have adopted the famed justintime production and "total quality control" strategies

Wcm World Class Manufacturing Sistema De Gestao Engenharia De Producao Evolucao

Chrysler World Class Manufacturing Academy Posts Facebook

Manufacturing Strategy Achieving World Class Manufacturing is a free online course that will give you an insight into the critical success factors for achieving worldclass status Learn about the requirements for worldclass manufacturing and examples of worldclass organizations Start this course today and improve your knowledge of manufacturing excellenceGlobal Quality through World Class Manufacturing Global quality through World Class Manufacturing "WCM aims to ensure that the FCA Group's facilities are flexible and competitive with the best in the world"Sergio Marchionne, CEO of Fiat Chrysler Automobiles NV Read more Global Quality through World Class Manufacturing Global quality through World Class Manufacturing " WCM aims to ensure that the FCA Group's facilities are flexible and competitive with the best in the world "Industry 40 and Lean Manufacturing In Lean Production, we usually say that information technology solutions are not so important for process improvements Instead, we normally advocate manual systems such as pen and paper

7 Steps To World Class Manufacturing

Pdf World Class Manufacturing Model In Production Management Semantic Scholar

World Class Manufacturing WCM combines engineering and manufacturing to produce automotive solutions for leading global brands The capabilities of the Group's 6 divisions deliver a complete product development service to customers looking to introduce innovative parts, assemblies and systems to markets worldwideWCM is a mindset based on a continuous improvement approach / 2World class manufacturing is a collection of concepts, which set standard for production and manufacturing for another organization to follow Japanese manufacturing is credited with pioneer in concept of worldclass manufacturing World class manufacturing was introduced in the automobile, electronic and steel industry

World Class Manufacturing Schonberger Richard J Amazon Com Books

The Main Tools For World Class Manufacturing Features And Description Business Building Information

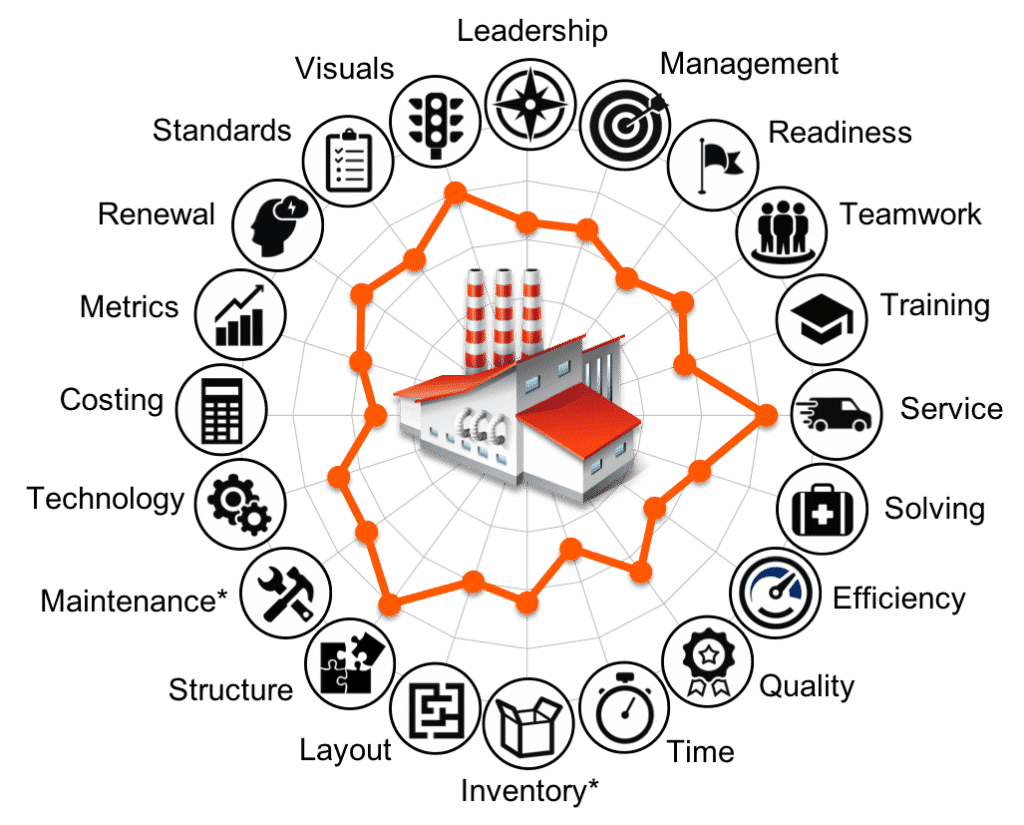

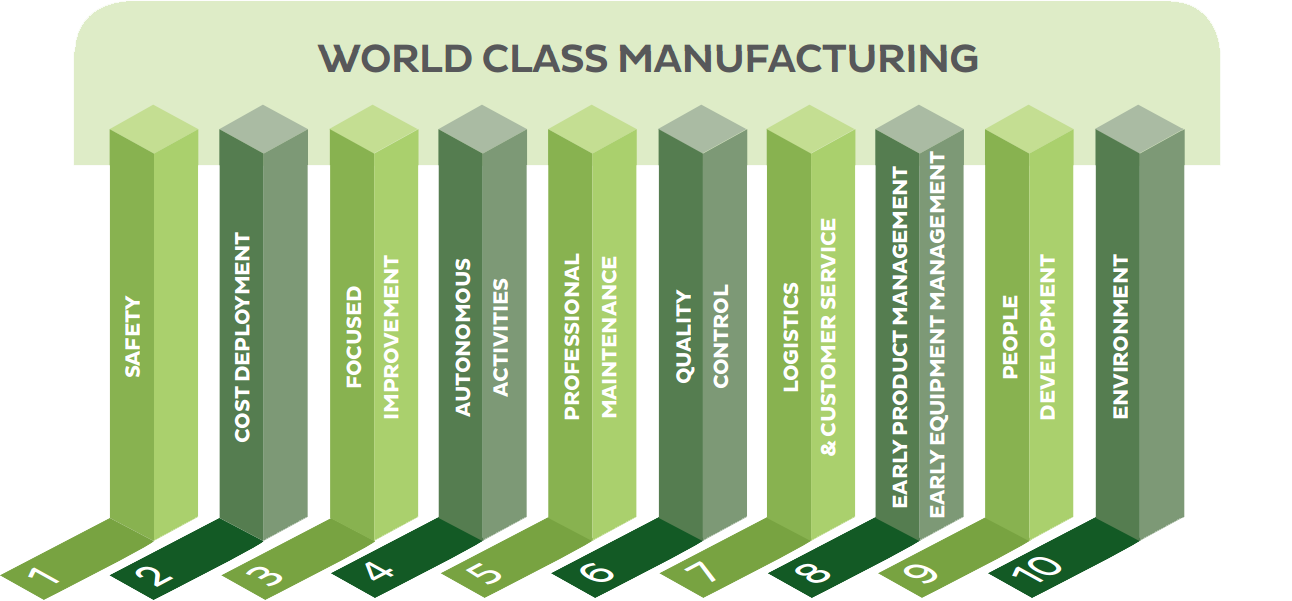

The content of World Class Manufacturing The WCM system is made up of ten technical and ten managerial pillars, illustrated as a temple (see below) The ten technical pillars are as follows 1) Safety (Occupational safety) 2) Cost Deployment (Distribution of Costs) 3) Focused Improvement 4a) Autonomous MaintenanceThe main tools for World Class Manufacturing Features and description KEY PERFORMANCE INDICES AND KEY ACTIVITY INDICATORS Industrial case study COMPANY BACKGROUND STATEMENT OF THE PROBLEM AND METHODOLOGY PLAN COSTS ANALYSIS AND LOSSES ANALYSIS (CD) FOR THE MANUFACTURING PROCESS (WO) AND FOR THE HANDLING PROCESS (LOG)World Class Manufacturing January 27, / in / by Kaufman Global WorldClass Manufacturing ensures a business enterprise can lead their markets and compete with anyone, anywhere producing a similar product It means that an enterprise has implemented and is sustaining a comprehensive, effective production approach throughout the extended value chain, one that all workers can understand and embrace

World Class Manufacturing Pillars Download Scientific Diagram

What Is World Class Manufacturing Wikilean

"Availability" is a key performance indicator in manufacturing;World Class Manufacturing WCM combines engineering and manufacturing to produce automotive solutions for leading global brands The capabilities of the Group's 6 divisions deliver a complete product development service to customers looking to introduce innovative parts, assemblies and systems to markets worldwideThe World Class Manufacturer has a ratio of 70 percent work to 30 percent costadded Quality Costs 4555 Percent Reduction The reduction in the cost of quality by 4555 percent is accomplished through a reduction in appraisal, internal and external failure costs

World Class Leadership Training Lean Manufacturing Training Technical Change Associates

Wcm World Class Manufacturing Ppt Video Online Download

The adoption of the principles of Total Quality, LeanWorld Class Manufacturing is a set of concepts, policies, techniques, and principles for operating and managing a manufacturing company The concept of World Class Manufacturing is based on the positive results achieved by Japanese manufacturing companies after World War II A common definition of World Class Manufacturing is when United States' companies began implementing Lean concepts in order to stay competitive in global marketsWorld Class Manufacturing In his bestselling book Japanese Manufacturing Techniques, Richard J Schonberger revolutionized American manufacturing theory and, more important, practice In that breakthrough book, he revealed that Japanese manufacturing excellence was not culturally bound

How Can World Class Manufacturing Improve Your Supply Chain S Effectiveness And Agility Nts

Wcm U1 Topic 5 World Class Manufacturing And Information Age Competition

In the real world, gathering and analyzing the DPMO yields another benefit knowing the type of defect may help isolate the cause To change the example above, suppose each defective coil failed the same test Then this might indicate it is valuable to determine what causes that failure So the process of determining DPMO has two major valuesIn fact, World Class Manufacturing is a manufacturing system defined by 6 International companies including Fiat Group Automobiles with the intent to raise their performances and standards to World Class level with the cooperation of leading European and Japanese experts and this includes all the plant processes including quality, maintenance, cost management and logistics etc from a universal point of viewProducts at the lowest possible cost level World Class Manufacturing WCM is the collective term to realize these objectives WCM was the result of many centuries' of production knowledge and ability Starting with the guild structure in the Middle Ages, this knowledge and ability evolved via the manufacturing in the 18th century, scientific management/mass production, sociotechnology and lean production in de twentieth century into the StateoftheArt manufacturing companies in the

World Class Manufacturing Fca Group

World Class Manufacturing The Next Decade Book By Richard J Schonberger Official Publisher Page Simon Schuster

Our mission is to help WorldClass Manufacturers become even more profitable Feel free to explore our website You will find several articles, videos, and other tools that will help you create an efficient and reliable production Click here Oskar Olofsson founded the company From our office in Stockholm, Sweden, we offer global consulting servicesThe ten pillars of World Class Manufacturing The implementation and management of WCM involves continuously capturing and analysing data, tracking, reporting and counteracting losses and directing initiatives for continuous improvement of production processes WCM professionals thus have the responsibility of coordinating the design, execution, measurement and optimisation of manufacturing processesWorld class manufacturing is the philosophy of being the best, the fastest, and the most agile producer of a product or service It implies continuous improvement of products and processes to remain an industry leader and provide the best choice for customers The Principles

Wcm World Class Manufacturing Pour Les Nuls Ithoughts Mind Map Template Biggerplate

World Class Manufacturing The Next Step Beyond Lean

World Class Solutions Global OEMs and Middle Market OEMs no longer need to choose between outsourcing to contract manufacturer or building vertical integration A Virtual Assembly Factory solution seamlessly integrates customer processes to provide a fully integrated and scalable manufacturing solutionHere are our "top six" essential manufacturing KPIs to get you started 1 Overall equipment effectiveness (OEE) OEE is a much talked about KPI and shows how manufacturing assets perform relative to their theoretical maximum potential Businesses that invest heavily in plant will find that OEE measurement is an essential metric to trackThe traditional accounting system is basically the manual or paperbased recording of the daily transactions such as prices, sales, the stock of a business or an organization (Bruno & Lapsley, 18) Efficient accounting process are essential to the successful growth and development of any business

World Class Manufacturing World Class Manufacturing Wcm Is A Process Which Integrates The Standalone Processes Of Jit Tpm Tqm Lean Manufacturing Ppt Download

Lean Production And World Class Manufacturing A Comparative Study Of The Two Most Important Production Strategies Of Recent Times

World Class Manufacturing Information And Free Guides

Wcm World Class Manufacturing A Ultima Tendencia Na Qualidade

Wcm World Class Manufacturing Ultima Tendencia Na Qualidade Linkedin Mujer De Negocios Ojos De Mujer Negocios

World Class Manufacturing 35 Slide Powerpoint

World Class Manufacturing

World Class Manufacturing Chrysler S Operational Excellence Presentations Supply Chain Innovation Enterprise

Improving Operations Performance With Wcm Technique A Case In Automotive Industry Business Building Information

World Class Manufacturing Makigami Info

World Class Manufacturing Saic Hongyan Official Website

Lean Production And World Class Manufacturing A Comparative Study Of The Two Most Important Production Strategies Of Recent Times

Solved Q A World Class Manufacturing Wcm Aims To D Chegg Com

World Class Manufacturing Wcm Companies In Bangalore By Leanmaintainance Issuu

The World Class Manufacturing Programme At Chrysler Fiat Co Better Operations

The World Class Manufacturing Framework 13 Download Scientific Diagram

World Class Manufacturer Strategy Organization Levels System Model Company Hierarchy Business System

The Keys To World Class Manufacturing Emaint

Management Systems Yaris Kabin

Unilevergulf Su Twitter Japanese Scientist Dr Hajime Yamashina Professor Emeritus At Kyoto University Created The Concept Of World Class Manufacturing The Premier Industry Benchmark For Manufacturing Here Are His Top Protocols That

World Class Manufacturing Cnh Industrial Sustainability Report 14

Euroblech 18 World Class Manufacturing Bystronic

Lean Assessment World Class Manufacturing Technical Change Associates

Implementing World Class Manufacturing The Complete Guide Third Edi Wcm Associates

World Class Manufacturing

World Class Manufacturing Pm Machine Ledger And Pm Calendar Continuously Improving Manufacturing

World Class Manufacturing Wcm And Implementing Strategies

The World Class Manufacturing Framework 13 Download Scientific Diagram

Good Start Implementation Of The World Class Manufacturing Project Centravis

World Class Manufacturing Group Linkedin

World Class Manufacturing At Marelli Automotive Lighting Brotterode

Pdf A World Class Manufacturing Implementation Model

Chrysler World Class Manufacturing Academy Year In Review Youtube

Fundamentals Of World Class Manufacturing Faber Infinite

Duke Offering World Class Manufacturing

The Lean Dimensions International

Wcm World Class Manufacturing Brands Of The World Download Vector Logos And Logotypes

Global Quality Through World Class Manufacturing Fca Group

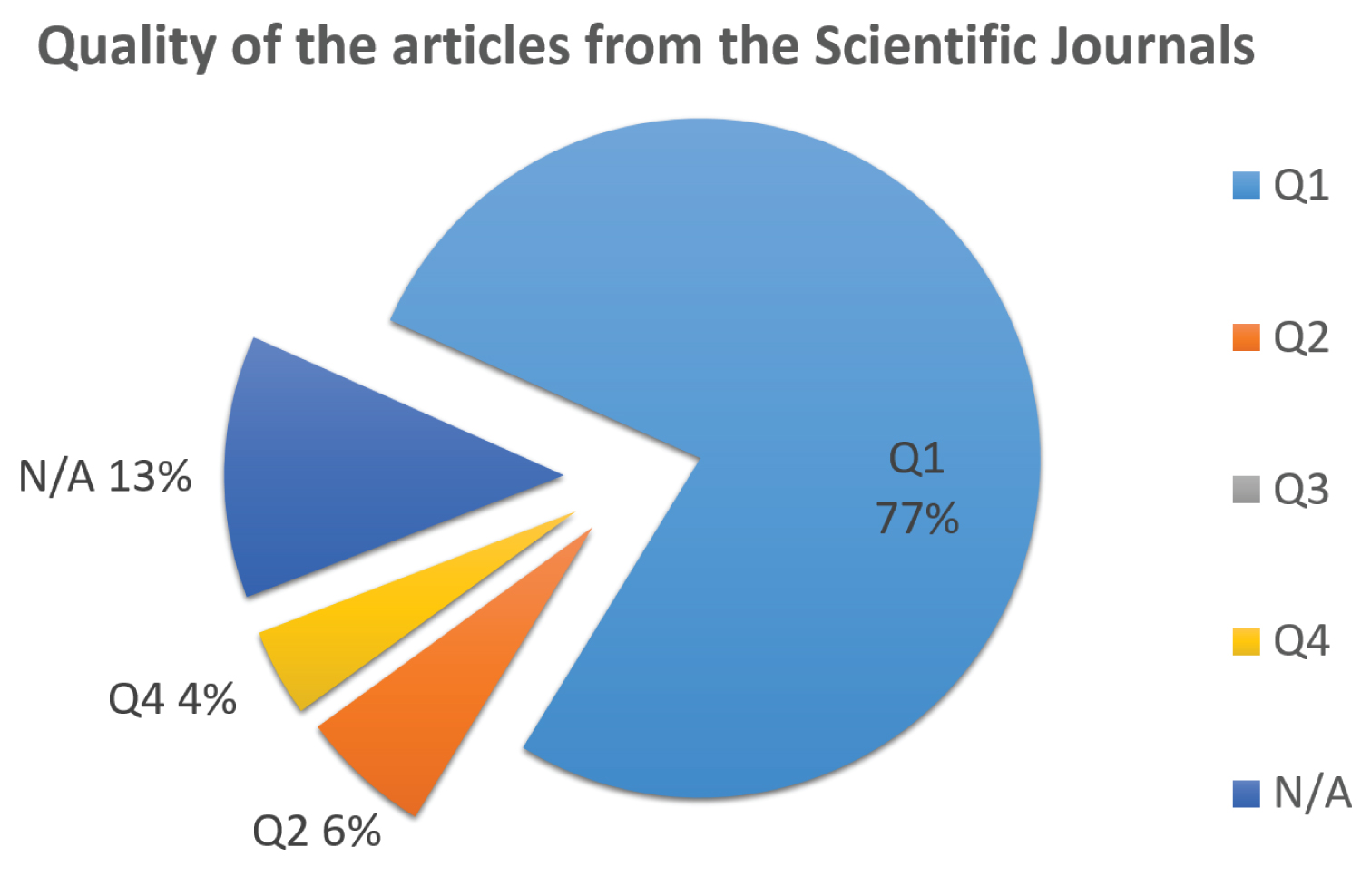

Knowledge Management And World Class Manufacturing An Initial Approach Based On A Literature Review

World Class Manufacturing World Class Manufacturing Concept

World Class Manufacturing Saic Hongyan Official Website

Ariston Thermo Conquers The Wcm Bronze Medal In Arcevia The Ariston Thermo Plant In Arcevia Successfully Passed The Wcm Audit By Conquering The Bronze Medal Which Was Awarded To The Company On 12th July The World Class Manufacturing Wcm

Skf Enters The World Of Manufacturing Using World Class Digital Technology

Lean Audit Operations Diagnostics Book Leanmap

World Class Manufacturing Cnh Industrial Csr 13

Column World Class Manufacturing Total Productive Maintenance Facade Quality Transparent Png

Oem Wcm World Class Manufacturing Alfra Lean Advisors

Wcm World Class Manufacturing And Its Applications In Plant Improvements

Syngenta Group Opens World Class Manufacturing Plant In Switzerland Business Wire

World Class Manufacturing Elica

World Class Manufacturing Lean Process Engineering The Wareham Group

Tpm 3 Levels Path To World Class Manufacturing Continuously Improving Manufacturing

3 Keys For World Class Manufacturing

The World Class Manufacturing Programme At Chrysler Fiat Co Better Operations

Underpinning The 10 Pillars Of World Class Manufacturing With Digital Technology

World Class Manufacturing Manufacturing Japanese Manufacturing Industrial Engineering

World Class Manufacturing Home Page

World Class Manufacturing Takes Center Stage At Chrysler Plants Wardsauto

Lodz Radomsko Wroclaw And Poprad Pass World Class Manufacturing Audits Whirlpool Corporation

Fundamentals Of World Class Manufacturing By Faber Infinite Medium

Kostwein Group World Class Manufacturing

Pdf World Class Manufacturing Wcm Model And Operational Performance Indicators Comparison Between Wcm Firms Semantic Scholar

Achieving World Class Manufacturing Free Online Course Alison

World Class Manufacturing Ppt Ppt Powerpoint

World Class Manufacturing Wcm Companies In Bangalore Seven Steps Global

Improve Your World Class Manufacturing Rating Ifm Electronic

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

World Class Manufacturing Truck And Weighbridge Management System

World Class Manufacturing Continuously Improving Manufacturing

Lvd Implements World Class Manufacturing Initiative Lvd Group

World Class Manufacturing Concept

World Class Manufacturing Information And Free Guides

World Class Manufacturing Magna International Office Photo Glassdoor Co In

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

How To Build A World Class Manufacturing Facility Navigate Content

0 件のコメント:

コメントを投稿